Factory-Made Blunt Plastic Needle for Safe Injection

Product Details

| Feature | Specification |

|---|---|

| Needle Type | Blunt Plastic Needle |

| Material | High-quality plastic |

| Size | Various sizes available |

| Color | Multiple options |

Common Product Specifications

| Specification | Details |

|---|---|

| Gauge | 18G to 25G |

| Length | 25mm to 50mm |

| Usage | Single-use |

Product Manufacturing Process

According to authoritative sources, the manufacturing process of blunt plastic needles involves precision injection molding techniques. The high-quality plastic material undergoes stringent quality control to ensure durability and flexibility. The design process incorporates ergonomics for easy handling, with rigorous testing for safety and efficacy. Studies highlight that these needles are engineered to minimize tissue trauma and enhance the comfort of medical procedures. Continuous research and innovation in this field aim to further enhance the performance and applicability of blunt plastic needles in both medical and cosmetic practices.

Product Application Scenarios

Blunt plastic needles are used across various applications, including medical settings for safe medication administration and cosmetic fields for filler injections. Research has shown that their blunt tips significantly reduce the risk of bruising and tissue damage. In veterinary medicine, these needles offer a stress-free solution for treating animals. Their usage in delicate procedures, like those involving hyaluronic acid in dermatology, ensures minimal patient discomfort. As technology evolves, the scope for using blunt plastic needles expands, promising enhanced safety and versatility in medical interventions.

Product After-Sales Service

- 24/7 customer support

- Warranty and replacement for defects

- Detailed usage guides

Product Transportation

Products are securely packed and shipped worldwide with tracking options, ensuring timely delivery.

Product Advantages

- Enhances patient comfort by minimizing tissue trauma

- Reduces risk of accidental needle-stick injuries

- High durability due to top-grade materials

Product FAQ

- What is a blunt plastic needle?

Manufactured in our factory, these needles have blunt tips and are crafted from high-quality plastic to ensure safety during procedures. They are designed to minimize tissue trauma and offer an alternative to sharp needles in certain applications. - How do blunt plastic needles differ from sharp needles?

Unlike sharp needles, blunt plastic needles produced in our factory do not penetrate the skin but are used where access is already established, minimizing the risk of injury and tissue damage. - Where can blunt plastic needles be used?

These needles are versatile and can be applied in medical, cosmetic, and veterinary fields, mainly for administering fluids or medications without creating new punctures. - Are blunt plastic needles reusable?

No, they are designed for single-use to ensure maximum hygiene and safety during medical and cosmetic procedures. - What sizes are available for blunt plastic needles?

Our factory offers blunt plastic needles in various sizes ranging from 18G to 25G, catering to different procedural needs. - How do I dispose of blunt plastic needles?

Used blunt plastic needles should be disposed of in designated sharps disposal containers to comply with safety regulations and prevent contamination. - What are the safety features of blunt plastic needles?

Factory-made blunt plastic needles feature rounded tips to significantly reduce the risk of needle-stick injuries and potential complications during use. - Can blunt plastic needles be used for all injections?

They are not suitable for initial skin penetration but are ideal for situations where an access point already exists, ensuring a safer alternative to traditional sharp needles. - Why choose our factory for blunt plastic needles?

Our factory leverages advanced technology and rigorous quality control to produce reliable and safe blunt plastic needles for a range of medical and cosmetic applications. - Are blunt plastic needles comfortable for patients?

Yes, they are designed to minimize pain and discomfort, making them more patient-friendly compared to sharp needles during certain procedures.

Product Hot Topics

- Blunt Plastic Needles in Cosmetics

The innovative design of factory-produced blunt plastic needles has revolutionized cosmetic procedures by significantly reducing bruising and tissue trauma, making them a preferred choice in the industry. Their ability to deliver fillers like hyaluronic acid with precision ensures a smooth and even application, enhancing patient satisfaction. As awareness of non-invasive techniques grows, these needles are gaining popularity for offering a safer alternative to traditional sharp needles. With ongoing advancements in technology, blunt plastic needles are set to become even more integral to cosmetic practices. - Safety of Blunt Plastic Needles

In medical environments, safety is paramount, and factory-manufactured blunt plastic needles provide a solution that addresses many concerns associated with traditional sharp needles. Their rounded tips reduce the risk of accidental needle-stick injuries, a common issue in fast-paced settings. This development has opened up new possibilities in patient care, contributing to safer procedures, less downtime, and quicker recovery. Healthcare professionals increasingly advocate for the use of blunt plastic needles to enhance safety and comfort in medical practices.

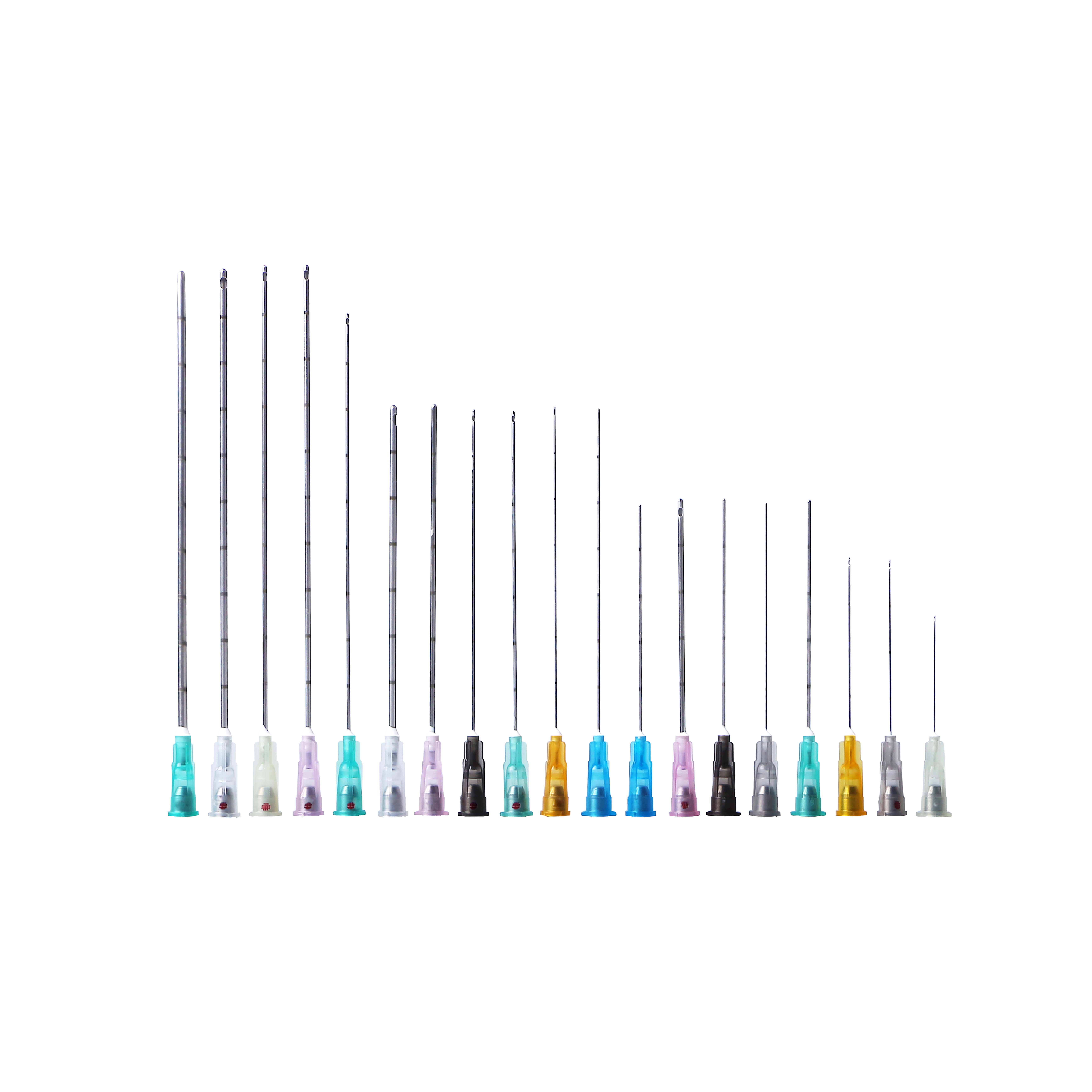

Image Description

There is no picture description for this product