Factory-Supplied Blunt Needle Use for Hyaluronic Filler

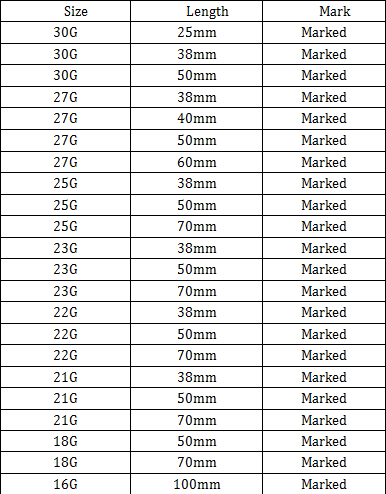

Product Main Parameters

| Gauge | Length |

|---|---|

| 14G | 100mm |

| 16G | 100mm |

| 18G | 100mm |

| 19G | 100mm |

Common Product Specifications

| Parameter | Specification |

|---|---|

| Material | Medical-grade stainless steel |

| Tip | Blunt |

| Usage | Hyaluronic acid filler injection |

Product Manufacturing Process

According to authoritative papers, the manufacturing process of blunt needles involves precision engineering to ensure safety and efficiency. The needles are crafted from high-quality medical-grade stainless steel, ensuring durability and minimizing the risk of infection. Each needle undergoes rigorous quality control to comply with international standards. This meticulous process guarantees that the blunt needles are safe for use in sensitive applications like hyaluronic acid filler injections. The factory ensures adherence to GMP and ISO standards, providing a product that is reliable and trusted globally.

Product Application Scenarios

As per authoritative sources, blunt needles are primarily used in medical and cosmetic procedures where reducing trauma and enhancing safety is crucial. Applications include injecting hyaluronic acid fillers into facial tissues, where the risk of intravascular injection is minimized. They are also employed in neuroaxial procedures to mitigate post-procedural complications. In veterinary settings, they aid in administering treatments with minimal distress. The factory's commitment to quality ensures these needles meet diverse application needs effectively.

Product After-Sales Service

We offer comprehensive after-sales support, including product warranties and customer service to address any concerns. Our factory is committed to ensuring customer satisfaction and maintaining long-term relationships.

Product Transportation

We ensure safe and prompt delivery through reliable logistics partners, with options for express shipping to meet urgent needs.

Product Advantages

- Safety: Minimizes risk of accidental punctures, ensuring patient and provider safety.

- Reduced Trauma: Designed to lessen pain and tissue damage.

- Cost-Effectiveness: Factory pricing provides competitive advantages.

Product FAQ

- What is a blunt needle? Blunt needles have a rounded tip used in applications where sharp penetration is unnecessary, minimizing tissue trauma.

- Why choose blunt needles for fillers? They reduce the risk of intravascular injections, important for safe filler applications.

- Are OEM/ODM options available? Yes, the factory offers customizable packaging and branding.

- What materials are used? High-quality medical-grade stainless steel is used for durability and safety.

- How do blunt needles reduce trauma? Their rounded tips prevent tissue lacerations, reducing pain and recovery time.

- What gauges are available? Available gauges include 14G, 16G, 18G, and 19G, suitable for various applications.

- Is training required for use? Basic training is recommended to ensure proper technique and application.

- Can these be used for neuroaxial procedures? Yes, their design minimizes complications like leakage and nerve damage.

- What is the shelf-life? Properly stored, they maintain integrity for several years.

- Are they suitable for home use? We recommend professional application for safety and efficacy.

Product Hot Topics

- Blunt Needle Use in Aesthetics: The use of blunt needles in aesthetic procedures like hyaluronic fillers has gained popularity due to their safety profile. By minimizing the risk of vessel penetration and tissue trauma, they have become an essential tool for practitioners. The factory's commitment to quality manufacturing ensures the needles meet the highest standards, gaining trust across the medical community.

- Factory Direct: Why It Matters? Sourcing blunt needles directly from the factory offers numerous advantages, such as better pricing, quality assurance, and customization options. Our factory ensures each product is manufactured under strict quality controls, making them a reliable choice for medical professionals. Direct partnerships also mean faster response times and personalized service, crucial in today’s competitive market.

- Innovations in Blunt Needle Designs: Recent innovations in blunt needle designs have improved their application in medical and cosmetic fields. Enhanced tip designs and material advancements have led to superior products that offer reduced patient discomfort and increased precision. Our factory stays at the forefront of these advancements, ensuring that clients receive the latest and most effective products available.

- Choosing the Right Blunt Needle: Selecting the appropriate blunt needle involves considering the gauge, length, and application requirements. Our factory offers a range of options and expert advice to ensure the right choice for every procedure. Understanding these factors can lead to more successful outcomes and increased patient satisfaction.

- Blunt Needle Safety Standards: Adhering to safety standards is paramount in the production of blunt needles. Our factory follows international guidelines and employs rigorous testing protocols to ensure each needle meets or exceeds safety expectations. This commitment to safety is reflected in our global reputation and the trust of medical professionals worldwide.

- Blunt Needle Use in Veterinary Medicine: In veterinary applications, blunt needles offer reduced distress for animals during medical procedures. Their use is crucial in administering injections without causing injury, providing a more humane approach to veterinary care. Our factory’s products are designed with these needs in mind, ensuring reliable and safe options for veterinarians.

- Comparing Blunt and Sharp Needles: Understanding the differences between blunt and sharp needles is key for medical professionals. Blunt needles are preferred in specific contexts where safety and minimal tissue damage are priorities. Our factory provides comprehensive information and guidance to help clients make informed decisions about needle selection.

- Blunt Needle Market Trends: The demand for blunt needles has been rising, driven by advancements in cosmetic and medical procedures. Our factory remains responsive to market needs, offering innovative solutions that cater to evolving demands. Keeping abreast of these trends can position distributors and practitioners advantageously.

- Environmental Impact of Blunt Needles: Our factory is committed to sustainable manufacturing practices, ensuring that blunt needles are produced with minimal environmental impact. By using eco-friendly materials and processes, we contribute to reducing the healthcare sector's overall ecological footprint.

- Customer Experiences with Blunt Needles: Feedback from practitioners highlights the ease of use and safety of our factory’s blunt needles. Positive experiences underscore their role in improving procedural outcomes and patient comfort. Engaging with customer feedback is critical to continuous improvement and innovation in our product lines.

Image Description