Importance of Quality Assurance in Medical Needles

In the world of healthcare, precision and reliability are non-negotiable. Blunt needles, though a niche item, play a crucial role in medication preparation and administration. Ensuring their quality from a supplier, manufacturer, or factory is paramount to patient safety and treatment efficacy. Consequently, quality assurance of blunt needles involves comprehensive evaluations that encompass material quality, compliance with global standards, supplier reliability, and more.

Understanding Global Medical Standards

Compliance with International Certifications

Global medical standards serve as a baseline to ensure the safety and performance of medical devices. When verifying the quality of blunt needles from a supplier, it's essential to consider certifications such as ISO 13485, FDA approval, and CE marking. These certifications ensure that the needles meet stringent safety, quality, and performance metrics, reducing risks associated with their use in healthcare settings.

Regular Audits and Inspections

A reliable manufacturer will conduct regular audits and inspections to ensure compliance with these international standards. Such practices often involve third-party auditors who provide unbiased evaluations of the manufacturing processes and the final products. Compliance documentation should be readily available for verification before procurement.

Evaluating Material Quality in Blunt Needles

High-Quality Raw Materials

Blunt needles must be crafted from high-quality materials, such as medical-grade stainless steel, to ensure durability and sterility. The use of substandard materials can lead to needle breakage, compromised sterility, and increased risk of contamination, posing significant health risks to patients.

Material Testing and Compatibility

Manufacturers must perform rigorous testing on the materials used to produce blunt needles. These tests assess tensile strength, biocompatibility, and resistance to corrosion. Ensuring material compatibility with medications and other medical devices is also vital to avoid adverse reactions during use.

Supplier Reliability and Credibility

Track Record and Reputation

A supplier's reputation can provide insight into their reliability and the quality of their blunt needles. Reviewing a supplier's history, customer feedback, and industry recognition can help determine their credibility. Reliable suppliers will have a proven track record of consistently delivering high-quality medical devices.

Partnerships and Collaborations

Suppliers who maintain partnerships with reputable healthcare institutions and other stakeholders in the medical field are more likely to adhere to higher quality standards. These collaborations often necessitate adherence to shared quality protocols and practices.

Cost-Effectiveness Without Compromising Quality

Balancing Budget and Quality

While cost is a consideration in any procurement process, it is critical not to compromise on the quality of blunt needles. Cheaper alternatives may result in higher long-term costs due to increased risks of defects and associated complications. A focus on cost-effectiveness should involve evaluating the total cost of ownership, including potential liabilities and maintenance costs.

Competitive Pricing Strategies

Manufacturers and suppliers can offer competitive pricing through bulk purchases or long-term contracts. However, it is essential that cost savings do not come at the expense of quality and compliance with safety standards.

Packaging and Sterility Maintenance

Integrity of Sterile Packaging

Proper packaging is vital to maintain the sterility and integrity of blunt needles. Packaging should provide a barrier against environmental contaminants while allowing ease of use in healthcare settings. Blunt needles must be individually wrapped and sealed to prevent contamination before use.

Packaging Innovations

- Use of materials that offer enhanced protection and are environmentally friendly.

- Packaging designs that incorporate tamper-evident features to ensure product safety.

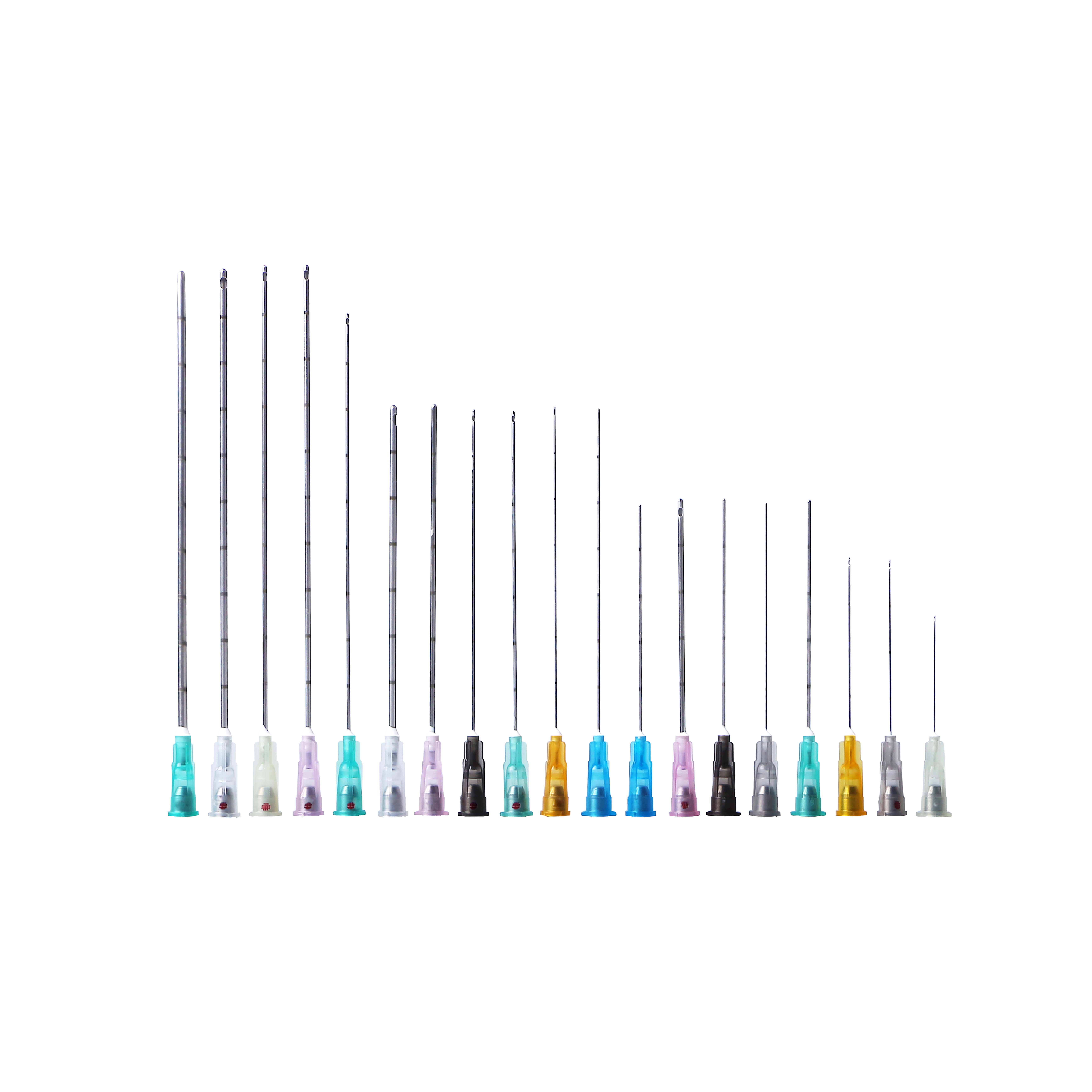

Diverse Medical Applications of Blunt Needles

Adaptability to Various Medical Procedures

Blunt needles are not intended for patient injections but are crucial in medication preparation. They are designed to draw medications from vials and ampules without compromising the sterility or integrity of the medication. Understanding the specific applications ensures their appropriate use and enhances patient safety.

Specialized Use Cases

In certain medical procedures, blunt needles are essential for preventing needlestick injuries and ensuring precise medication dosing. Their role in reducing injuries makes them indispensable in high-risk environments.

Ensuring Compatibility with Other Medical Devices

Seamless Integration with Syringes

Blunt needles must be compatible with various types of syringes and medical equipment to ensure seamless integration and prevent procedural delays. Compatibility testing with different systems is necessary to guarantee operational efficiency.

Testing for Cross-Device Compatibility

- Assessment of needle-syringe connections for secure and leak-proof interactions.

- Appropriate dimensional standards to fit multiple injection systems without modifications.

Sustainability and Eco-Friendly Practices

Use of Sustainable Materials

The shift towards sustainable practices in the healthcare industry is gaining momentum. Manufacturers can adopt eco-friendly materials and production processes to reduce environmental impact. This includes using recyclable or biodegradable packaging and reducing resource consumption during manufacturing.

Ethical Manufacturing Practices

- Commitment to reducing carbon footprint in production and distribution.

- Adherence to ethical standards in labor practices, safety, and environmental conservation.

Steps for a Smooth Procurement Process

Streamlined Ordering and Delivery

A seamless procurement process ensures timely availability of blunt needles without compromising quality. Companies should establish clear communication channels with suppliers to facilitate efficient ordering, tracking, and delivery.

Quality Control and Feedback

Regular quality checks and prompt feedback mechanisms help maintain a high standard of products. Suppliers should be open to receiving feedback and making necessary adjustments to improve product offerings continually.

Conpuvon Provide Solutions

Conpuvon offers a comprehensive approach to ensuring the quality of blunt needles through rigorous quality control processes and strategic collaborations with reputable partners. Our commitment to high standards and customer satisfaction ensures that all products meet stringent safety and performance criteria. By integrating sustainable practices and leveraging technological advancements, Conpuvon remains at the forefront of providing reliable and effective medical supplies tailored to meet the diverse needs of healthcare providers globally.

User hot search: needle blunt

Post time: 2025-08-08 17:20:04